cracking the glass code.

We have grown accustomed to metal and concrete…

Read MoreThe Chilean 100 peso coin has a copper-nickel center in an aluminium-bronze ring. On one side, it shows a Mapuche Indian Woman and on the other a coat of arms with the value. Or rather – it should show that. After shipment of forty million coins from the Netherlands to their destination country, it appeared that an estimated one percent of the coins showed missing chips and discoloration. An on-site sorting machine was urgently required and Demcon built it within four weeks.

The time pressure was unbelievable. The engineering team worked day and night to get a system up and running. Starting point was a mechanical coin seperator provided by the customer. It enabled presenting the coins to the actual inspection system one by one. This heart of the system was made from of-the-shelf components.

Visual inspection of the coin took place when the coins were in free fall. Each coin was photographed from both sides simultaneously and the picture analysis was the basis for the decision ‘accept’of ‘reject’. This decision making process literally took place in a split second: six coins passed along the vision system per second. When accepted they were blown off on a conveyor-belt, when rejected they landed in a container underneath. This order may sounds counter-intuitive, but minimises the risk of false positives (rejected coins landing between the accepted coins).

Demcon also applies the approach to vision inspection of vegetables, fruits, flowers, eggs and automotive lamps. Many other applications are possible.

There were two additional hurdles that made life more complicated for the engineering team. The first issue: as all coins were already shipped to Chile and couldn’t leave the country as a consequence of contractual agreement, the system couldn’t be trained with ‘real deal’ rejected coins. And as the system can be trained, but isn’t self learning, the engineers had to ‘make’ reject coins with resembling chipping and discoloration. As tiny deviations could be acceptable, the size of the affected region and the total amount of pixels showing deviations were taken into account to define an acceptable threshold value. After successful testing, the system was shipped to Santiago. Upon arrival, it appeared that some adjustments had to be made with the real coins. This tweaking succeeded. It had, however, to be repeated when it was discovered that the coins were manufactured in two batches which were somewhat different. This could also be solved by tweaking. In the end both the end customer as the manufacturer were satisfied with the solution Demcon had provided.

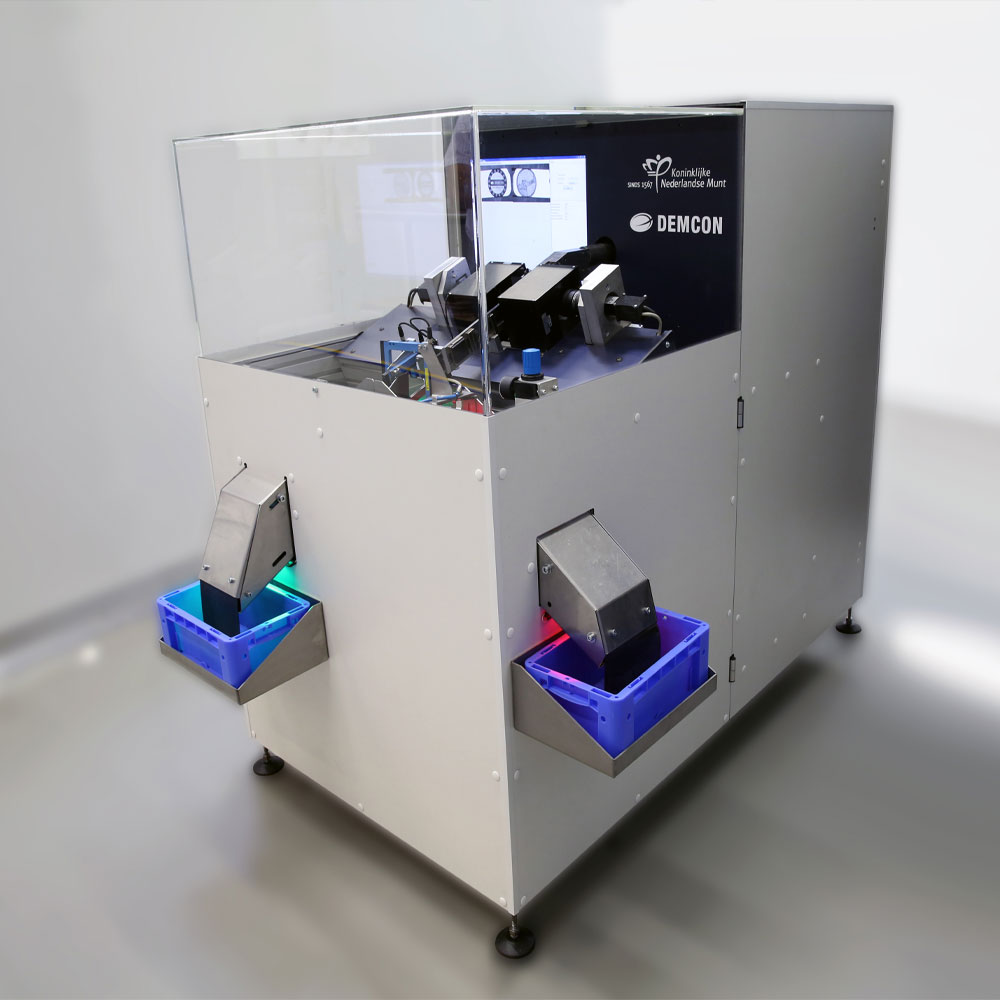

The system was built for this assignment only. After its deployment in Chili we could acquire it from the customer. We fitted it with a better housing and lighting and now use it as a trade fair demo for vision systems. Attention guaranteed by the tingling sound!